In the field of industrial automation, integration of robotic arms has proven to be an transforming force, altering the manufacturing landscape and production processes. With the advent of advanced technology robotic arms, sometimes referred to as Arm robot industrial, have emerged as essential tools that offer incredible precision, efficiency and safety across a myriad of industries. This article examines the diverse capabilities of robotic arms and their impact on business operations in Australia.

Robotic arms are mechanical devices that simulate the actions of human arms with greater power and precision. These automated solutions are used extensively in fields such as automotive manufacturing and electronics assembly. Pharmaceutical companies also make use of them because of their accuracy. The ability to program robotic arms allows seamless integration into diverse production environments. They offer flexible motion and adaptability to varying operational requirements.

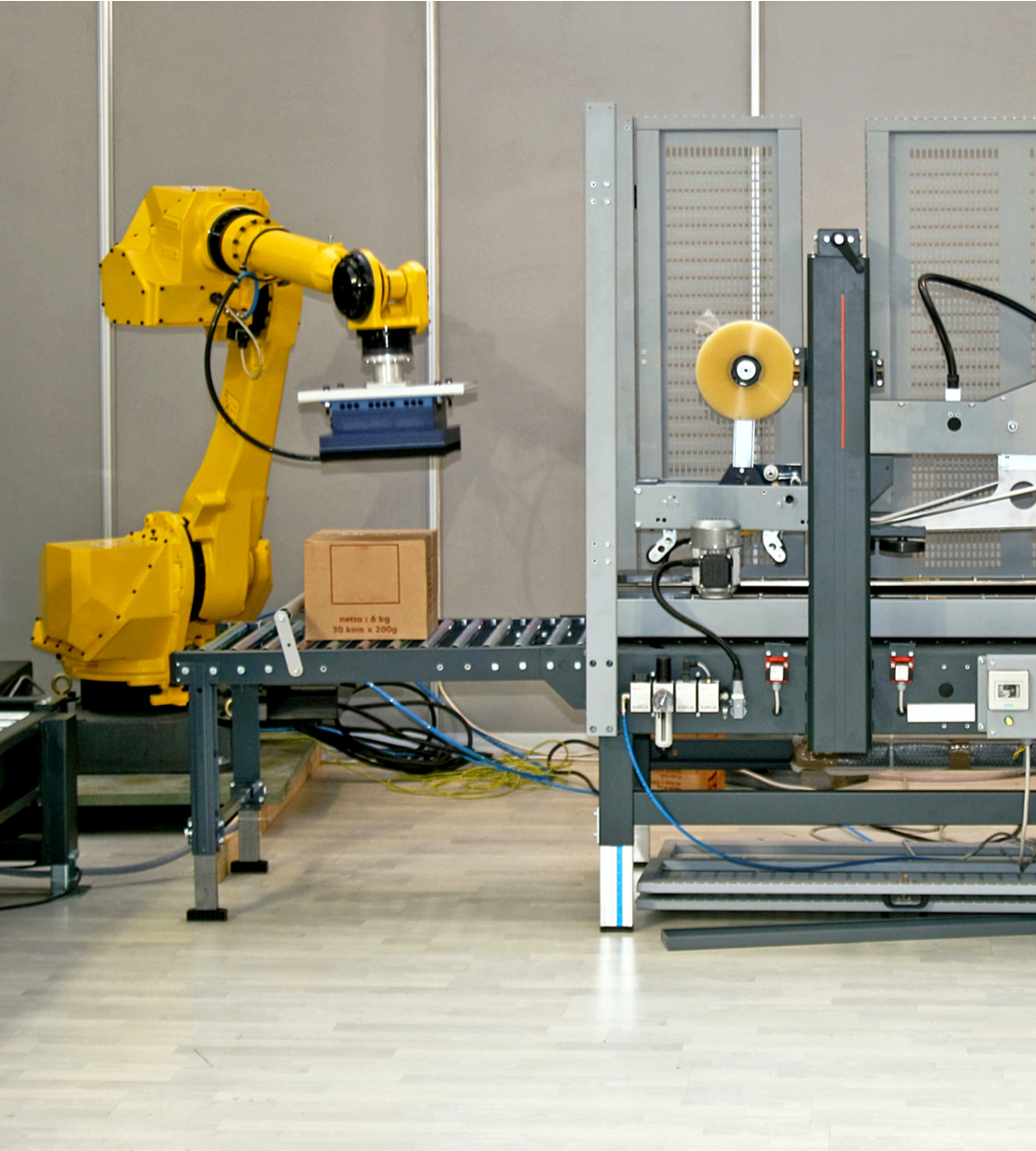

The robotic arm is a key component of modern automation, represents a sophisticated kinematic chain of joints that can move capable of rotating and performing linear displacements with remarkable precision. The robotic arm can navigate intricate spatial configurations, operate objects with precision and protect humans operating it. Robotic arms have become a necessity to businesses, allowing them to streamline manufacturing processes and improve efficiency in operations.

One of the key features of robot arms is the use of end effectors. They are the functional equivalent to human hands. End effectors, which are typically specifically designed for specific tasks play an essential role in determining the nature of the applications that robotic arms can perform. Robot hands that have specialized end effects are able to accomplish a wide range of tasks, from lifting and grasping heavy loads to securing delicate components. For more information, click Arm Robot Industrial

Within the context of industrial automation, the introduction of robotic arms have brought in a new era of innovation and productivity. Robotic arms allow businesses to improve their manufacturing processes as well as reduce human error and enhance the quality of products. The seamless integration between robotic arms as well as automated systems have led to significant advancements in operational efficiency, allowing companies to respond to growing demands with unprecedented speed and precision.

Robotic arms create a transformative effect that goes beyond automation. They are fundamentally changing industrial processes. Industrial robotic arms have not only improved existing manufacturing workflows, but also opened up the possibility to new methods of production. The ability of robotic arms to perform tasks in difficult or hazardous conditions has increased workplace safety and opened up new possibilities for manufacturing processes.

The evolution of robotic arms technology has also led to the development of end effectors tailored to specific industry requirements. These modern end effects, which are equipped with the latest gripping and sensor technology, have widened the possibilities of applications for robotic arms.

Companies in Australia are in a unique position to improve their competitiveness and operational capabilities when they take on the potential of robotic arms automation. The integration of robotic arms into industrial workflows will enable long-term growth, boost overall productivity and dramatically transform manufacturing. With a focus on precision engineering and efficiency robotic arms are poised to explore new frontiers in industrial automation, helping enterprises to attain unprecedented levels of efficiency and operational quality.

Conclusion: The integration of robotic arm industrial or robotic arms is an important step forward in the field of industrial automation. Robotic arms, thanks to their unparalleled precision, flexibility and safety features have redefined modern manufacturing. They offer businesses a competitive advantage in a marketplace that is becoming more competitive. Businesses can reap the benefits as Australia takes on robotics technology. This includes improved productivity, efficiency in operations and the ability to innovate.